How To Get Started With Mold Customization

Are you in need of a custom mold but don’t know where to start? We can help! There’s many things to consider when creating the perfect mold for your brand. Here’s the first steps!

What is your method of deposit?

When it comes to filling molds you have three options, an automated line, a universal depositor or a pour and scrape method. They all have their pros and cons but you will need to know which method you plan on using to decide what kind of mold you need.

Automated machines require less operator work and can produce thousands of gummies an hour, but you’re limited in the number of cavities per mold and cleaning the machine in between batches can be time consuming. Molds are typically made of metal and attached to conveyor belts.

Universal depositors are stand alone depositors where the operator hand feeds molds under the depositing nozzles. The nozzles can be slightly adjusted to align with the cavities on the mold.

With the pour and scrape method you need minimal equipment and cost and clean up is simple and easy, but it requires more man power and can sometimes be inconsistent. Your method of deposit will truly depend on the size of your operation and the level of automation you prefer. Knowing your equipment setup is critical and should be the first thing you decide!

What kind of mold do you need?

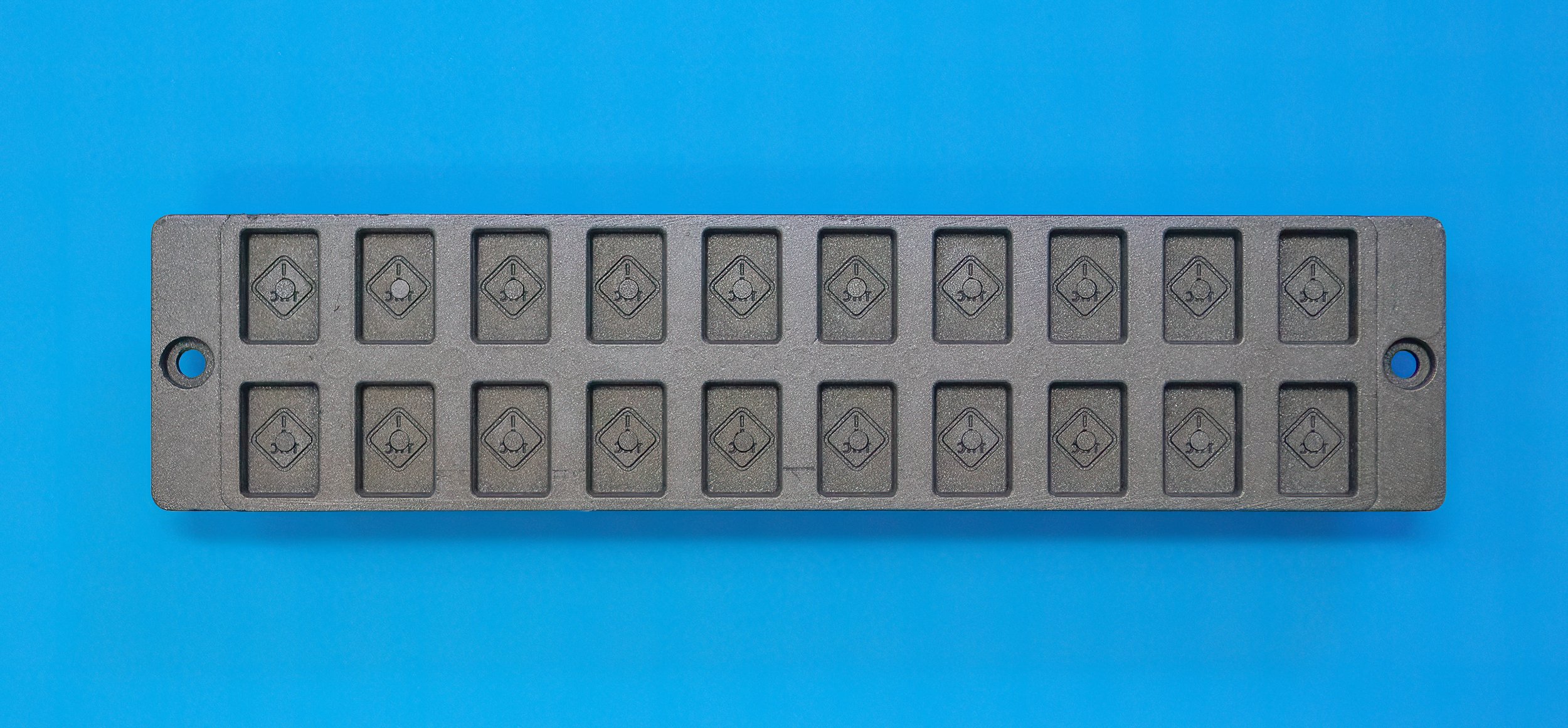

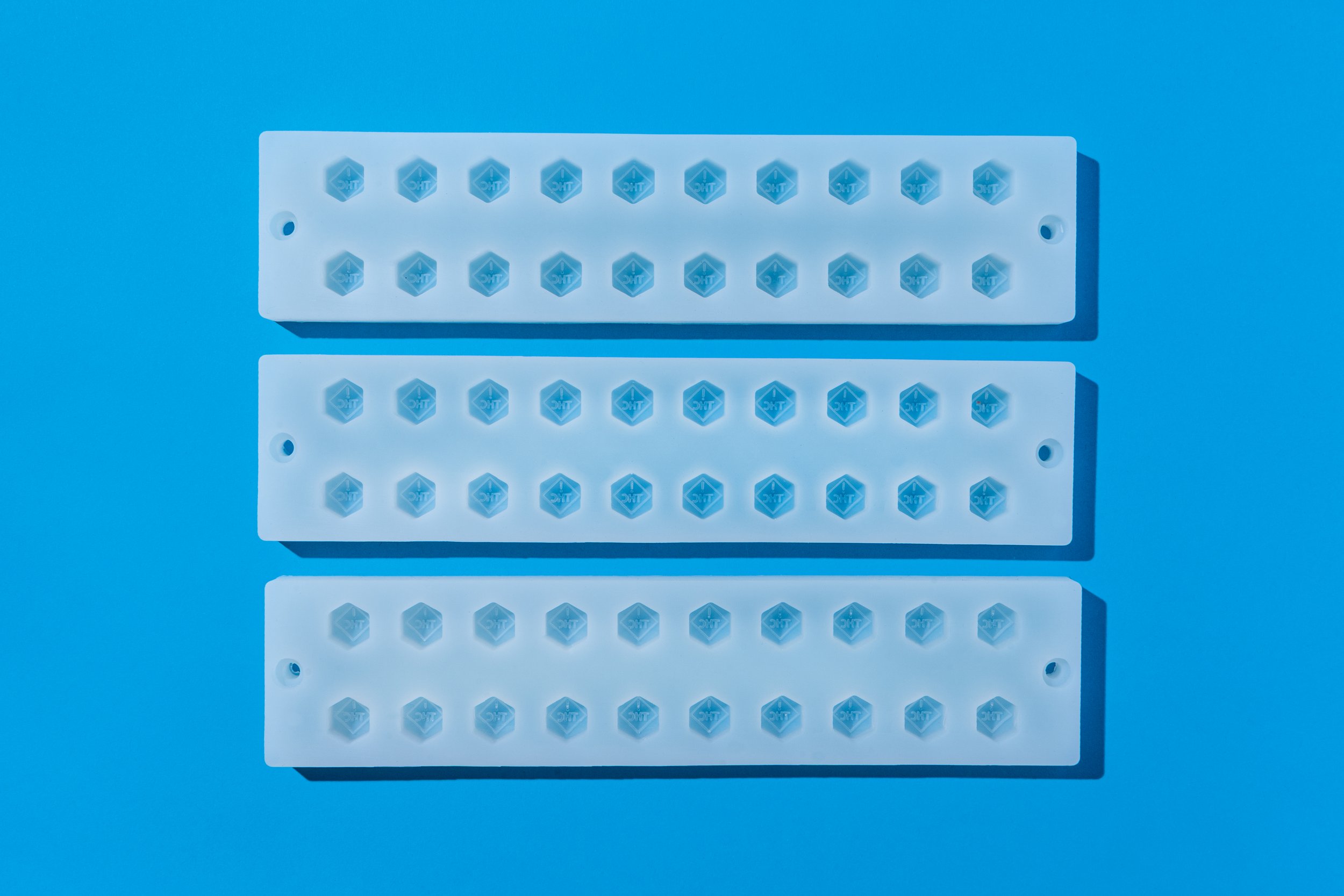

Our molds aren’t just for gummies! They can also be used for candles, ice cubes, hard candies and chocolate. Our gummy molds are made of platinum grade silicone only from the US and our chocolate molds are made of thermoformed (PETG) plastic.

What size do you need?

When you’re looking to get a custom mold made you’ll want to have an idea of the diameter, specific LxWxH and your target net weight per piece. If you plan to use the molds for gummies you must keep in mind that detail will play a huge part. The more detail in the mold the harder it will be to see in gummy form, but if being used for candles, hard candies or ice the detail will be much more visible. This will also decide how many cavities per mold you will get. Try to imagine your ideal mouthfeel and choose a size that best represents your brand and product.

What design features do you want?

Different design features can include:

Customizing your candy with your brands logo embossed or debossed on top of a shape.

Fun shapes like shooting stars, gems or fruit.

Adding symbols for regulatory requirements.

Scoring to indicate a specific serving size.

How many molds will you need?

This will be based on the size of the batch you’ll be making. Each mold has a specific number of cavities so depending on how many gummies you’ll need to produce you may need to order numerous molds. For example, if you want to make 1,000 gummies and each mold has 200 cavities you’ll need 5 molds to make your batch.

Once you’ve figured out these first questions you’re ready to start your custom mold journey!